7 solutions to skyrocket kitchen efficiency

16 October 2015

Kitchen layouts should be made by the laziest people on earth, ideally. They understand why every single step matters. And it really does. At this point, we’ve been through a few versions of the kitchen layout for our first pizzeria in the US. The main goal was to think ahead of all the processes that might affect our productivity and efficiency in the kitchen. We hope that by getting rid of some unnecessary steps, we’ve made ourselves a room for handling more orders during the rush hours.

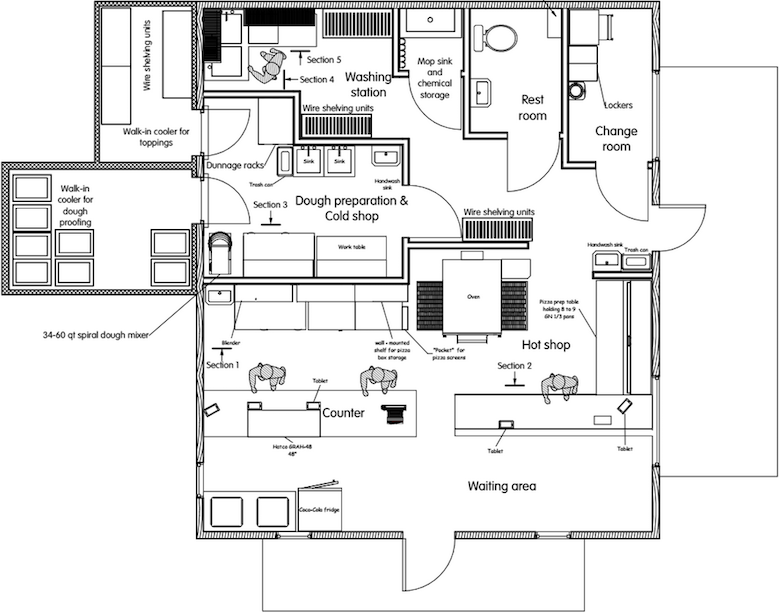

The latest version looks like this:

These are 7 steps we’ve undertaken to improve our restaurant's layout.

1) More independence!

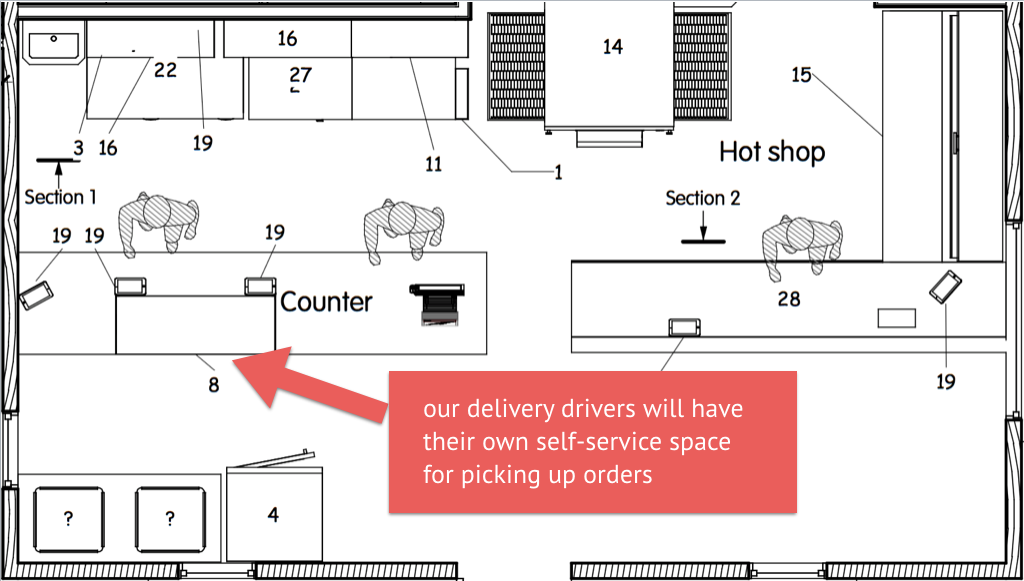

Usually, a delivery person takes orders from the shift supervisor, but this can delay delivery if the supervisor is busy helping at the cash register or in the kitchen. Why can’t the driver get the pizza by himself? Good question. At Dodo Pizza Oxford, our delivery drivers will have their own self-service space for picking up orders. They won’t disturb a shift supervisor every time they return to the store; all the orders will be displayed on tablets, and the driver can see the status of the next one in line and pick it up from the shelf. That would convert a pizza delivery guy into a delivery superman flying in and out of the kitchen without wasting precious time.

2) Two is twice as good as one

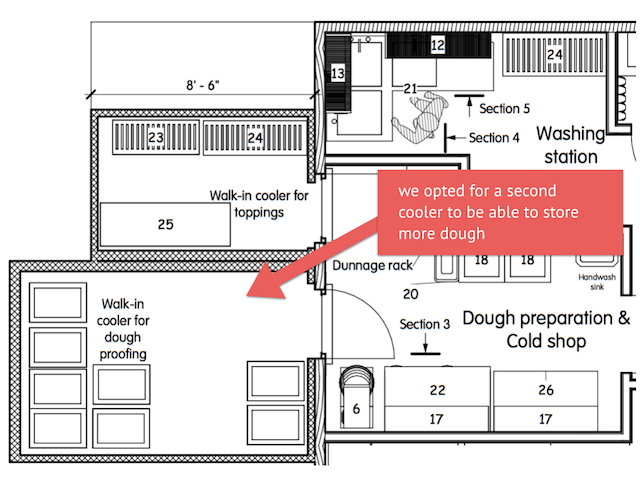

Pizzerias are usually run with one walk-in cooler. The reason is simple—these things are pretty expensive. Besides that, you need to allocate extra space for them, since they're big. We definitely can't say that we have more money than we need or a lot of free space in the Red House. Still, we opted for a second cooler to be able to store more dough and prepped ingredients. This will allow us to make dough in larger batches less frequently, which will save time for the employees. If you make dough, you have to clean everything after you finish. If you make dough just once a day instead of twice, you'll only have to clean once. So that’s definitely a great time saver. Plus, for the sake of saving the space, we placed the coolers outside the building.

3) Less is more sometimes

The porch was initially going to be used for a manager’s room and dry storage. Our team had been warned by an architect that reconstruction of the porch would demand serious investments and might negatively affect the timeline of the project. Therefore, we just won’t have a manager’s room, and we’ll rent some extra dry storage space from our neighbors. That approach leads to some advantages. One square foot costs much less at a self-storage facility than at a downtown building. Why keep things downtown and pay more when we can pay less and deliver everything we need to the pizzeria straight from storage?

4) Kitchen like a little factory

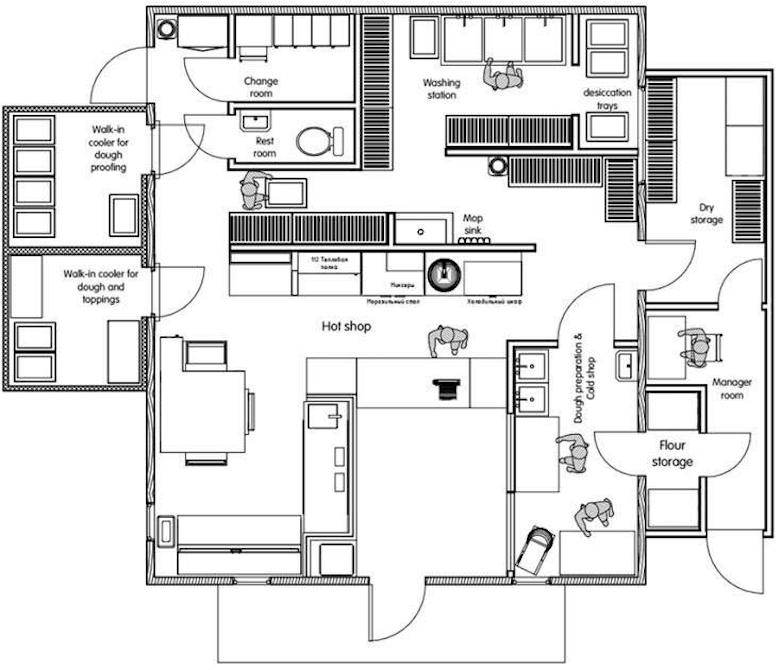

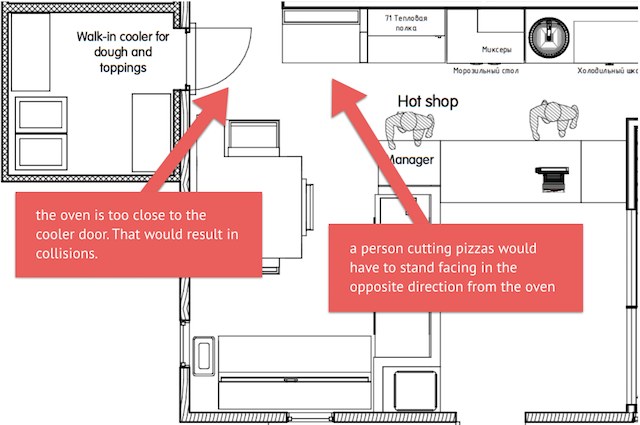

This is one of our first layouts, and if we stuck to it, it would have been a disaster.

The oven is too close to the cooler door. That would result in collisions. A person cutting pizzas would have to stand facing in the opposite direction from the oven, so he or she would have to turn around every time to check if a pizza is ready. You might think that's not a big deal. But during rush hours, little obstacles or tiny inconveniences can ruin everything.

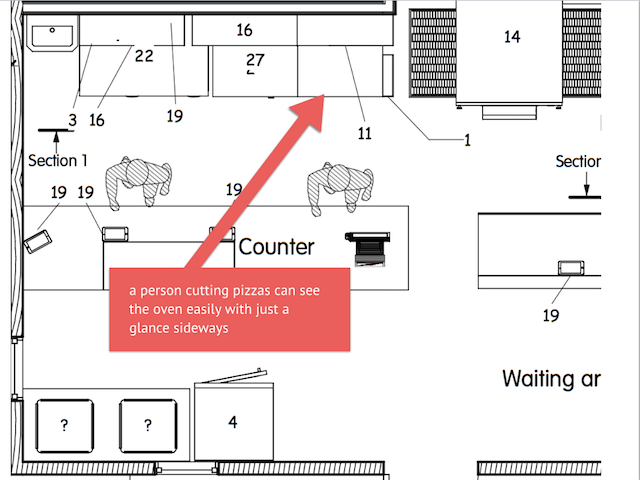

So we rethought the layout several times until the whole chain of pizza preparation processes got in line. Now there are no doors in the way of our pizzas and the person cutting them can see the oven easily with just a glance sideways.

5) Search for the win-win

The Coca Cola fridge has been moved from the cashier zone to the waiting area so that our guests and delivery drivers will be able to help themselves with drinks. That's the same logic I mentioned earlier—making employees and clients as independent as possible. Customers who can choose their own drinks from a vending machine keep the flow going better than when they have to choose from an overhead menu. At the same time, a shift supervisor would not need to spend time facilitating this process, which allows for more focus on making products and coaching employees. Win-win.

6) Every square foot must work

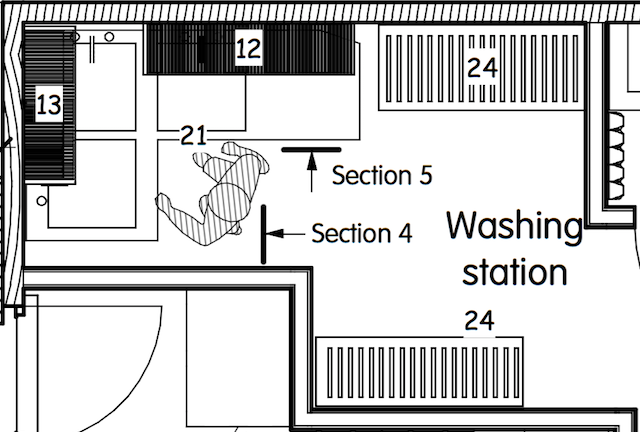

We devoted special attention to every single corner and corridor of the kitchen, making everything work and serve a specific purpose. Our three-compartment sink is a good example of this approach. Usually 3 sinks are placed in line, but doing so takes much more space, and to tell the truth, it's not handy at all, because you have to move from one to the other while you’re washing stuff. However, if you place them in the corner, like we did, you save not only space but also your energy and time, because you'll be able to wash anything you need without leaving that spot.

7) Size matters

The work table for base preparation has been lengthened to allow two people to make pizzas simultaneously during the rush hours. You might say that lengthening a table goes against the main principle of compactness. But have a look from a different angle. Our pizza is hand-tossed. Hand-tossing requires more space than making pizzas using a pizza press. If we say “No!” to the opportunity to make two pizzas simultaneously, in the end, we’ll lose productivity during the rush hours. We believe that getting rid of extras should never go against the core of our concept. In our case, managing a huge amount of orders quickly is essential.

So, now you see that being lazy might result in doing things more efficiently.

Invalid optin campaign ID